Expansion & New Equipment Start-up

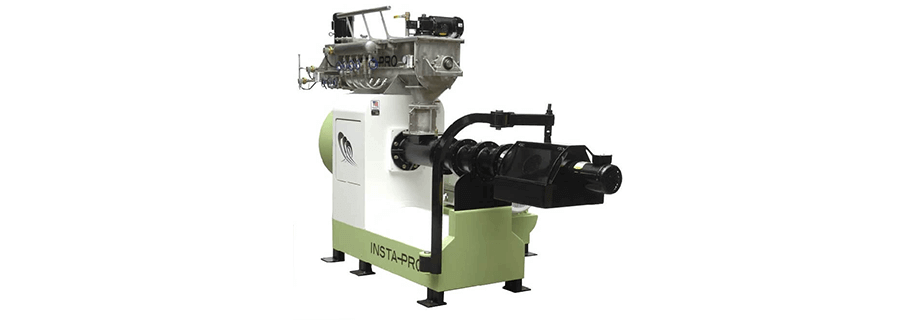

I’ve traveled a lot over the years, but this trip was special in that it was my first start-up for our new Model MS3000 medium shear extruder. We have been working on this machine for three years in R&D, so I was ready to prove and confirm the value of this machine to the market.

Due to the extensive testing we did on this piece of equipment, we were very confident in the performance of the extruder. The cutter head has been completely redesigned to enhance the appearance and overall versatility of size and shapes for the traditional pet food and fish food products. Computerized touch screen technology make the controls user friendly with the added advantage of being able to better track maintenance and monitor temperature trends of the process. Overall the start-up went extremely well. We had a few bugs to get out of the controls, but that’s typical of a start-up. Due to the amount of interaction we had prior to the visit, the customer was well prepared. The required steam harness, feed system and finished product conveyance posed no problems whatsoever.

Once we got running, we tested with four different formulas of dog food and even made an exotic rat food. The customer had existing Insta-Pro high shear extruders, and we were able to improve the quality and shape of their existing product line. Also, the production capacity exceeded our best case expectations and we were able to help the customer improve the performance of their existing high shear extruders. The customer was very pleased, and recent communication confirms that the new extruder is continuing to perform to expectations. They are already looking to the future with plans to possibly expand into the fish feed market. I really enjoyed this trip because of all the work we put into this project and being able to see it, as they say, bear fruit. I also enjoyed reconnecting with a customer who prior to the purchase of the new machine, we hadn’t heard from a lot the last few years.

I would also like to mention that the MS-3000 comes with a new operator’s manual. This is thanks to a new member of the Insta-Pro team Kevin Hansen, Design Engineer. Kevin is currently in the process of updating all of our manuals, which will be a great benefit to our customers. As always we strongly encourage our customers to make contact with us when they have questions. We are happy to share our knowledge to help them be successful while maintaining a healthy business relationship. If you’re not a customer but interested in our new Medium Shear or any of the other numerous processes we support, please feel free to contact us.