How Much You Can Save With Improved Layer Feed Conversion

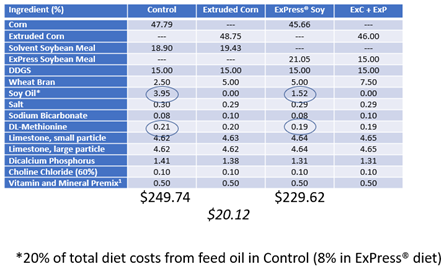

In 2022, Virginia Tech University conducted a feeding trial that compared Insta-Pro ExPress® soy meal with Conventional soybean meal (SBM) in layer diets. The results showed an improved feed conversion ratio (FCR) from 1.927 to 1.892 when substituting ExPress® meal for solvent-extracted SMB into the diet. FCR measures the feed intake divided by the egg mass produced. There was also a notable cost reduction. The diet containing ExPress® meal costs $229.62 per ton, a $20.12 reduction than the SBM diet, at $249.74 a ton.

The above table shows the cost difference in the amount of methionine and soy oil needed to complete the diet. ExPress® meal contains 6-8% residual oil, while typical SBM is less than 1%. We know that the protein in the extruded and pressed ExPress® meal has not been over-processed and is highly digestible. At the end of the day, the feed cost per bird was $0.25 less than the conventional formulation with SBM.

So, stepping back and looking at a 1,000,000-hen layer farm, what does that mean for the bottom line?

At $0.25/bird savings during 15 weeks of the laying phase alone, that is $250,000 in feed cost savings. If you feed the birds for 4 more turns of 15 weeks, you can see the potential savings over the course of a year.

So, How Does it Work?

Traditionally, solvent-extracted soybean meal (SBM) is a meal that has had the oil removed by using hexane solvent, then approximately 1% of the oil is put back into the meal. The SBM is then brought to a feed mill, mixed with the other ingredients for the formulation, and then pelleted or fed in a mash.

The alternative mechanical way is very similar; however, soybeans are processed through the extruder, then oil press to make highly-digestible, mechanically extracted soybean meal and soybean oil. These can be directly incorporated into a complete diet formulation and fed as either pellets or mash, improving feed ratios and reducing costs.

The equipment required consists of soybean intake, cleaning, milling, extruding, oil pressing, cooling, final hammermilling, and bagging/storage. While this may seem complex, it is much simpler than a solvent-extraction plant. Insta-Pro’s equipment is designed to be user-friendly, scalable, and accessible for operations of all sizes, with quick and easy expandability. Check out our animation showcasing a 4 TPH system for a visual overview. Here is a great animation that demonstrates briefly what a 4 TPH system looks like.

If you are interested in reducing layer diet costs or learning more about processing your own ExPress® meal and would like a feasibility analysis to see what kind of ROI is possible, please reach out to us today!