Dairy Farmers: Providing Added Value to Corn for Dairy Cows

In several countries the dairy industry had a difficult year in 2020, as in many other industries, the pandemic caused consumers to make significant changes in their consumption habits by adjusting their purchases in the supermarket and affecting farmers at the end of the chain of the dairy industry. The high prices of cereals have affected profits and in some cases they have worked at a loss, so it is important to create strategies to obtain the greatest benefit from the ingredients in the dairy cows’ feed, in this case corn.

Corn has always been an excellent ingredient in the feeding of dairy cows, among other things due to its high starch content starting from its basic presentation as raw grain, however if the grain is whole, the starch will not be used by the cow due to its low digestibility under these conditions, then the first strategy arises of grinding the corn to increase the contact surface, breaking or gelatinizing the starch molecules to make them more available and more digestible, however the gelatinization of the starch of the ground corn would barely reach 25% which is very low, with a rumen digestibility of only 51% as described by Insta-Pro Nutritionsist Kathleen Mayo in a previous blog: (https://www.insta-pro.com/en/blog/nutritionandtechnologies/high-shear-dry-extruded-products-for-highly-digestible-rumen-microbial-protein-in-dairy-part-ii-high-shear-dry-extruded-corn/)

Another strategy used to process the corn is steam flaking, a process widely used in several farms, with this, the gelatinization of the starch increases even more, reaching values of 74% but with a little increase in its digestibility in rumen reaching just 54 %. Expanded corn reaches very similar values with approximately 78% gelatinization of the starch.

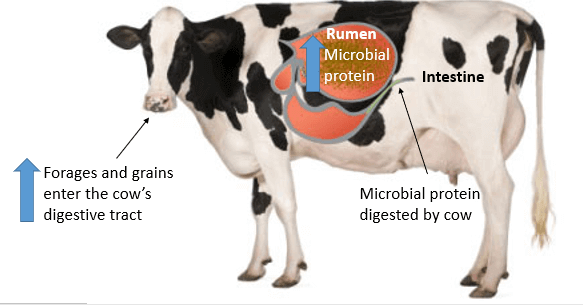

Is there a better and more efficient process than those already mentioned? The answer is yes, high-shear dry extrusion is the most efficient process to add value to corn and be much more efficient in difficult times. Insta-Pro has developed the ideal equipment to process corn and obtain the greatest benefits with the extruder model 2000-CG that guarantees a stable and efficient process with a modern cutting head to obtain small Hi-Gel™ Corn discs with a very attractive shape. With this process, the gelatinization of the starch reaches levels of 90% and the digestibility in the rumen rises above 72%. The Hi-Gel™ Corn discs have a very low ruminal passage rate, so they remain in the rumen and increase the production of ruminal microbial protein, obtaining an increase in efficiency in milk production and its components (milk fat and milk protein).

It is for these and other reasons that a great strategy to obtain the maximum benefit from this grain in feeding dairy cows is high shear dry extrusion. If you have any questions feel free to contact the Insta-Pro International Sales team or Nutrition team.