4 Nutritional Points to Consider When Purchasing an Extruder

High-shear dry extrusion from Insta-Pro® International allows the production of nutritionally superior ingredients from oilseeds like soy. This is by design – high-temperature, short-time cooking with dry extrusion provides a thorough cook, practically measured as temperature, while minimizing time. This short-time aspect of the process is critical because nutrients, especially the amino acids in protein, such as lysine, do not tolerate cooking for more than a minute. The cook time with dry extrusion lasts only seconds, preserving protein quality.

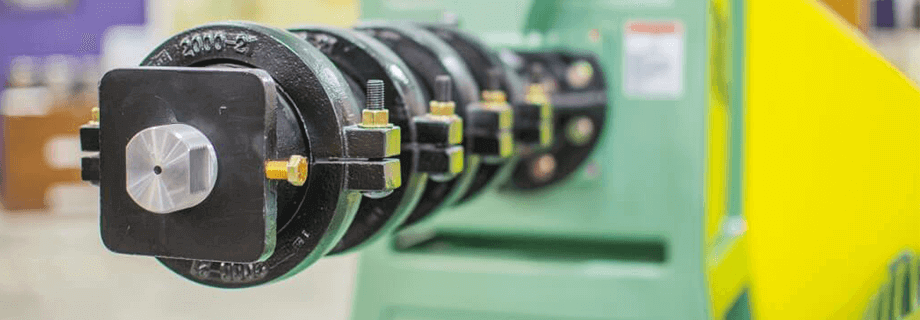

It’s important to understand that many things are happening during extrusion. While temperature is commonly and easily measured, other forces are at work in the extruder barrel. As temperature rises, pressure, shearing forces, mechanical energy, and other factors are changed (mostly increasing); these effects must be accounted for as well.

How is this done? When it’s difficult or impossible, we turn to measuring the quality of the end products. This is why we’ve conducted animal feeding trials in addition to lab testing for nearly 50 years to understand and control our processes.

Controlling the dry extrusion processing temperature allows you to maximize the following:

- Deactivation of naturally occurring antinutritional factors, such as trypsin inhibitors, because they hinder digestion and performance

- Maximization of metabolizable, or usable, energy for growth

- Increasing in lysine digestibility – usable amino acids for productive purposes

- Maximization of body weight gain – faster growth equals fewer days to market

Can your non – Insta-Pro extruder or process achieve all of this? Likely not. Don’t assume that it can.